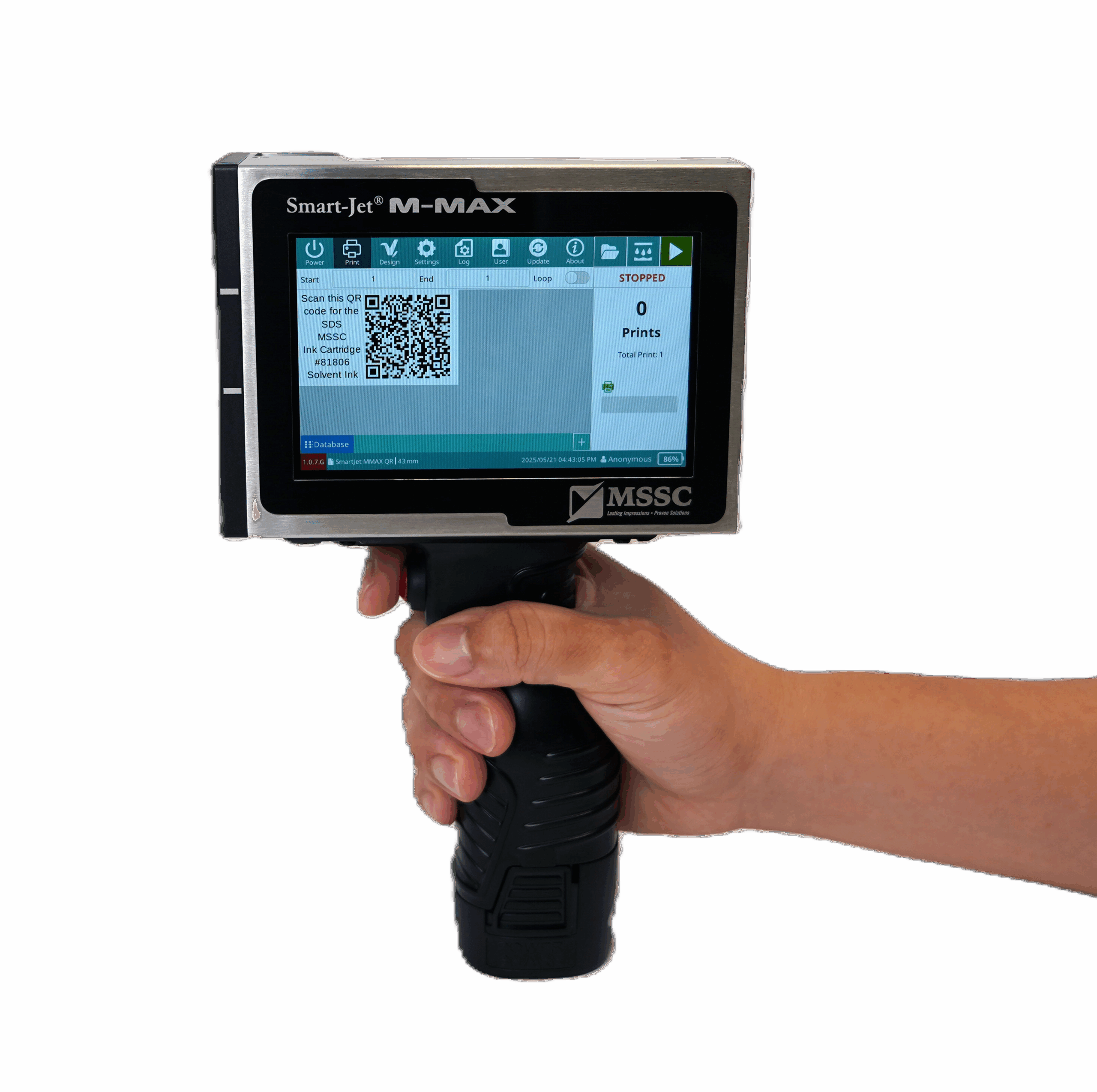

MSSC Smart-Jet® M Max Handheld Printer

Overview

The MSSC Smart-Jet® M Max handheld printer is a powerful, portable solution designed for versatile, on-the-go industrial marking and coding. It features a compact design, allowing operators to easily carry and use it in various locations. Capable of printing characters up to 1 inch high, it supports a full range of print options, including text, lot numbers, dates, shift codes, logos, graphics, database imports, and an extensive selection of linear and 2D barcodes such as QR, Data Matrix, and GS1 formats. Users can easily create and customize messages using free, web-based design software, with no limits on line count or vertical positioning, then transfer them to the printer via USB or Wi-Fi. The M Max also offers simple backup and restore functionality, along with POD Print Command Protocol for seamless remote data import and integration into existing workflows. The Smart-Jet M Max handheld uses ink cartridges, which are quick to replace, minimizing downtime during production. It supports printing on both porous and non-porous materials, including paper, plastic, and metal. Connectivity options include Bluetooth, enabling wireless data transfer and remote control. With its large character capability, versatile connectivity, and robust printing performance, the Smart-Jet® M Max delivers high-resolution, professional results wherever they’re needed.