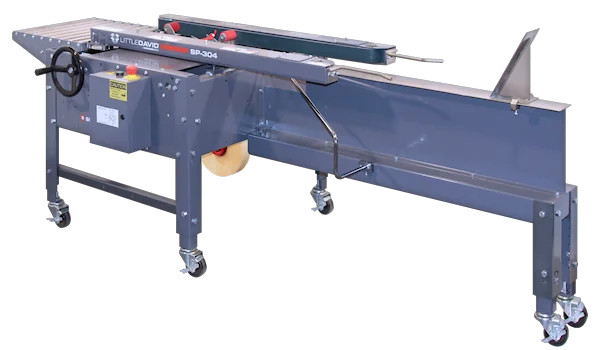

Loveshaw SP-304BO Case Former

Overview

The Loveshaw SP-304 Bottom Only Case Former is a robust, semi-automatic machine designed to form, fold, and seal the bottom of corrugated cases. It streamlines packaging operations by delivering up to 24 cases per minute, enhancing productivity in high-demand environments. The SP-304BO is an ideal case former for the erecting and bottom-sealing cases for future use. The machine offers reliable case forming with minimal operator intervention, thanks to its intuitive design and efficient performance. It features a compact footprint, making it suitable for operations with limited space. Adjustable for various box sizes, the SP-304BO is highly versatile. The heavy-duty construction ensures long-term durability, even in demanding settings. It integrates smoothly into existing packaging lines, providing consistent and high-quality case forming. Maintenance is simplified due to its accessible components and clear operational controls.